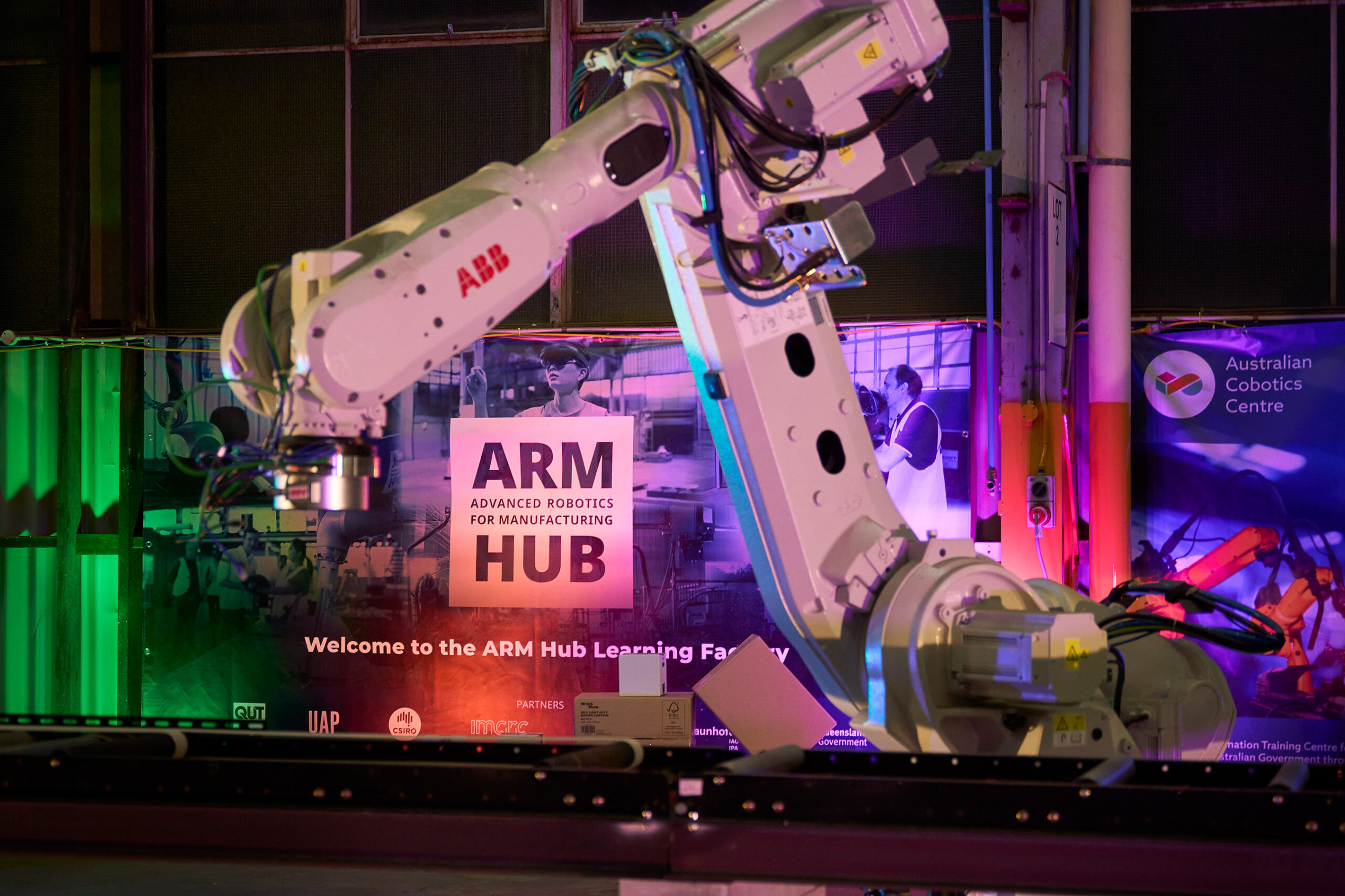

We are celebrating the official launch of the new ARM Hub AI Adopt Centre today!

The multi-partner Centre was launched at South by Southwest (SXSW) Sydney as part of the Australian Government’s AI Month celebrations.

ARM Hub Founder and CEO Professor Cori Stewart said the Centre was a ‘front door’ to expertise, support and services that will foster AI-driven business growth.

“Many businesses feel uncertain about where to start with AI. The common barriers include a lack of data readiness, a skills gap, or simply not knowing which AI applications are relevant to their business. The Centre is offering access to practical solutions to help businesses move forward with AI,” Professor Stewart said.

Professor Stewart said the Centre would play an important role in helping Australia’s SMEs (which make up 96% of all industry) scale their innovation, preventing it from going offshore.

She said SMEs using the Centre will be tapping into expertise from internationals Microsoft and Databricks, as well as local AI SMEs Data and Knowledge Enterprise and Raytracer.

“Australian industry is ready to invest in AI and robotics to increase its productivity and competitiveness. We’ve designed this Centre to provide practical pathways to de-risk the adoption and use of AI and Generative AI, helping businesses to make the most of this fast-moving frontier of technology.

“Research shows AI and automation are expected to increase Australia’s productivity by up to 150%. We want industry to be transforming their operations for long-term success by having their data organised, structured and ready for AI.

“The ARM Hub AI Adopt Centre is here to make businesses better using the benefits of AI and Generative AI. Our collaboration of 28 partners includes AI and robotics experts across Australia, which ensures we are delivering the best skillsets into all corners of the country.

“Over the next three years, we expect to engage with up to 30,000 SMEs on their digital transformation journeys.”

The key Features of the ARM Hub AI Adopt Centre are its practical guidance for SMEs; a collaborative, industry-led network; and a focus on ethical and safe AI practices to ensure sustainable business growth.

In May this year, the Australian Government announced the establishment of four centres under its AI Adopt Program to facilitate the safe and responsible use of AI by SMEs.

The ARM Hub AI Adopt partners are here.