ARM Hub CEO and Founder Dr Cori Stewart summarises her opening remarks for the Australian Governnment’s recent House Standing Committee inquiry in Brisbane this month.

I raised three factors critical to manufacturing in Australia at the House Standing Committee on Industry, Science and Resources for Developing Advanced Manufacturing in Australia.

1. Australia’s population decline

Our declining population demands we innovate to drive new productivity into manufacturing and make the most value out of our working population. Technology must be a force multiplier here.

Australia’s birth-rate is 1.6, and a nation needs 2.1 to maintain its population. It means we will have about 2.5 people in 2050 of working age (15-64) for every older Australian.

These statistics have Australia on a trajectory of hard-to-reverse population decline often described as the “Japan Dilemma”.

Australia needs a strong technology sector to do the jobs we don’t or cannot do. We need to use our human labour in more valuable and rewarding working roles if we want to secure a manufacturing workforce at all.

We need a strong robotics, automation and artificial intelligence capability. We know that robots creates jobs, they don’t take jobs.

Australia is 30th of all countries in its ratio of robotics to the human workforce, which is poor given at the same time we are globally recognised as leaders in robotics research and robotics innovation more widely. Australia also has the lowest manufacturing capability of all OECD countries.

Incremental change, uncoordinated policy efforts, and unstable or uncertain investment environments will hamper our ability to be a modern competitive manufacturing nation.

2. Australia is poor at scaling enterprises

This includes scaling manufacturing as well as the technology businesses like robotics that underpin our manufacturing ability.

Recently, the Tech Council of Australia released its Shots on Goal report saying:

‘Australia needs a lot more scale’up capital to match the United States on a per capita basis. While we do meet comparative investment environment to the US for Series A funding and we not too bad at Series B funding, for Series C and D – the scale-up stage characterised as when you employ a large workforce and export to the globe – Australia will need to increase funding by five times above BAU growth to match the United States by 2030 on a per capita basis. At our current rate Australia will face an expected gap in scaleup funding of $53b by 2030.’

The Australian Government’s National Reconstruction Fund and the Industry Growth Program are critically important in this space and will need to invest in ‘intangibles’ such as software, which is the smart part of manufacturing.

It is critical we scale-up manufacturing, which means accessible investment. It is the only way we can realise a net gain from cooperative trade policy settings with the U.S. (e.g. the Inflation Reduction Act, the proposed Defence Production Act, and the Climate, Critical Minerals and Clean Energy Transformation Compact).

3. Coordinated national approach to industry policy

We strongly believe a coordinated national approach to industry policy would coalease Australia’s efforts and resources, making us more competitive.

I would like to build on the idea of Australia’s network of Factories of the Future to facilitate open innovation and collaboration in manufacturing, which enables investment in key sovereign capabilities to be translated across industry sectors.

We also recommend further investment in strategic programs for industry:

• technology accelerators

• global supply chain innovation programs

• workforce development programs

• manufacturing precincts of global renown.

Australia needs to set the foundation for a coherent and successful industrial transformation strategy.

A strong network of Factories of the Future will tackle Australia’s narrow trade and industrial structure and create the industries and jobs of the future.

Only manufacturing can provide the foundations for national reconstruction because it will deliver the innovation, productivity and competitiveness and jobs we need to ensure greater sovereign capability and economic complexity, including diversification of our export mix.

Key findings from the two case studies were:

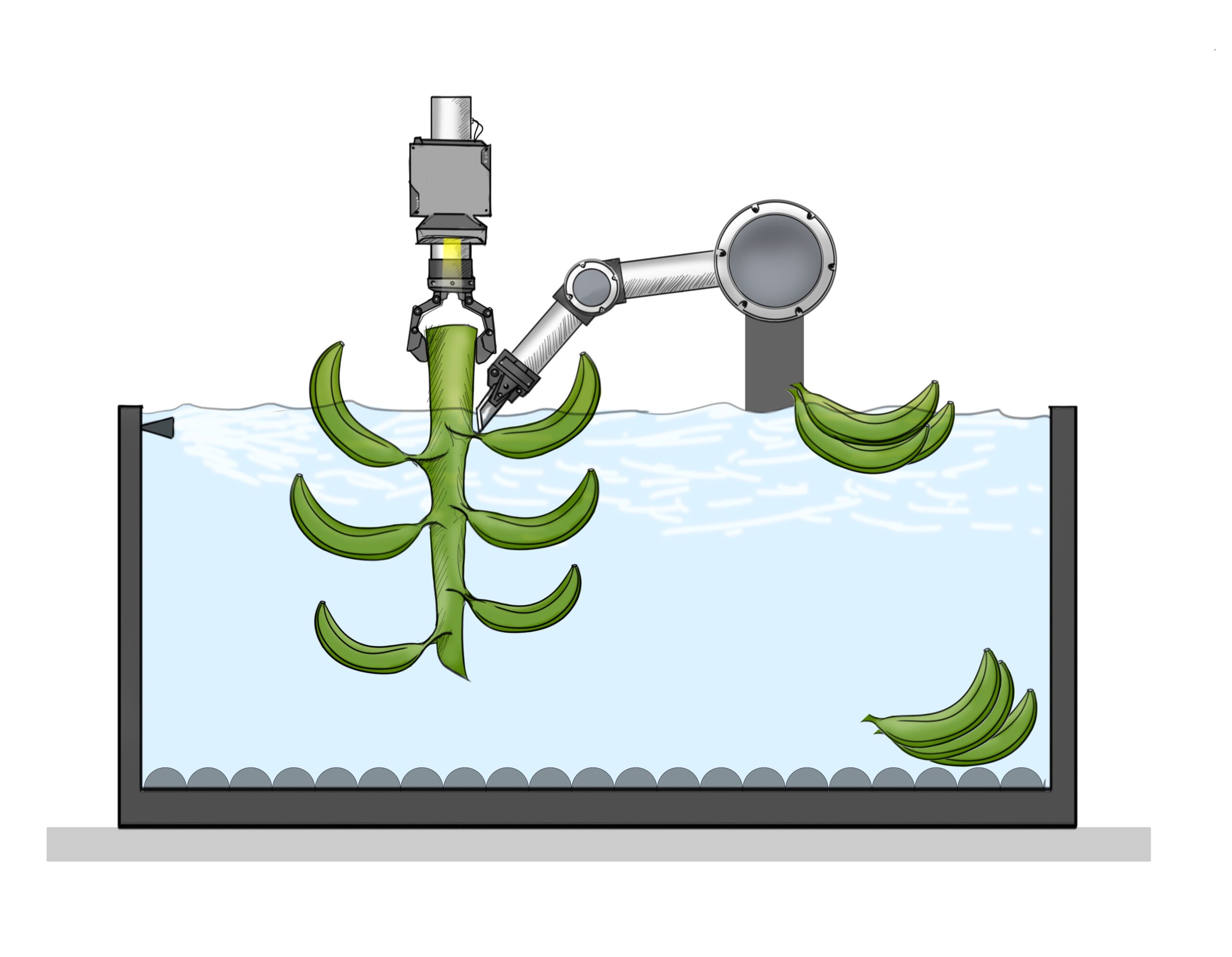

Key findings from the two case studies were: ARM Hub COO Mr Samuel Jesuadian presented on outcomes of Advanced Manufacturing projects at ARM Hub and led a small group on a tour of the ARM Hub factory.

ARM Hub COO Mr Samuel Jesuadian presented on outcomes of Advanced Manufacturing projects at ARM Hub and led a small group on a tour of the ARM Hub factory.