ARM Hub worked with the Hopkins Centre, Spinal Life Australia (SLA) and Advanced Queensland Fellow Dr Camila Shirota, a Lecturer at Griffith University, to provide our expertise in design, additive manufacturing, and robotics for the Increasing remote care solutions for the people with disability (Spinal Injury) project.

We participated in four multi-disciplinary innovation workshops at the SLA Healthy Living Centre in Cairns, Far North Queensland, to co-design solutions for people living with spinal cord injury. The co-design workshops involved people with lived experience of spinal cord injuries, allied health practitioners, designers and manufacturers from across Australia.

Our work on this project was made possible by the Queensland Government’s Essential Goods and Supply Chain Program support for manufacturers to make essential goods, consumables, and devices.

The challenge:

An estimated 250,000 to 500,000 people globally suffer a spinal cord injury. In Australia alone, the lifetime cost of care and lost economic activity for someone with quadriplegia is $9 million and the total current cost to the community for all spinal cord injuries exceeds $2 billion annually. A therapy or equipment that gives people back or increases their independence will also save our community enormous costs.

In addition, Covid-19 significantly disrupted the delivery of healthcare, especially in areas that require physical interaction, such as disability and rehabilitation.

This project uses a co-design process to develop pertinent solutions of AT (assistive technology) and helps to document the areas of rehabilitation and disability services that are vulnerable to disruption.

Through the innovation workshops a range of challenges were identified with the targeted design being the development of individually customised weather safe hand grippers for wheelchair. This is a critical issue for wheelchair users, who can push their hand rims 2000-3000 times per day and RSI injuries are common.

Matching the hand rim profile to the user can increase efficiency.

What we did:

We participated in an eighteen-month multi-stakeholder project providing expert advice for manufacturing healthcare solutions that involved automation, industrial design, and additive manufacturing technologies.We recruited manufacturers in relevant areas to participate – one in all-terrain robotics, one in furniture, and two in 3D printing – and our design representatives worked with clinicians, people with a spinal injury and a family member, and members of the research team.

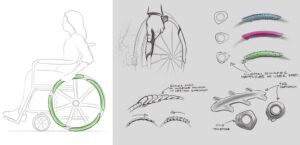

Initial concept sketches of wheelchair gripper designs

Using feedback from the workshops, we developed a range of 3D printed hand grippers which were tested with a wheelchair user and refined. During this process we developed seven different designs comprised of different materials such as silicon, PLA, ABS and Carbon fibre filament.

In the fourth workshop all designs were trialled by wheelchair users at SLA Cairns in a collaborative workshop to assess and evaluate and inform future development.

Outcomes:

Based on user feedback, recommendations were made for future product development and wheelchair users expressed a clear interest for the product. Users especially liked being involved in the process and being able to tailor much needed products to their custom requirements.

We built prototypes and undertook testing of 3D printed hand grippers for wheelchair.

This project helped establish an innovation process including online consultation and workshop with end-users to prioritise 3D production for prototypes.

The project piloted the translation and implementation of a priority solution into practice.

MORE INFORMATION:

ARM Hub Project Leader – Dr Muge Fialho Leandro Alves Teixeira

Tel: +61 7 3138 4263

Email: muge.teixeira@qut.edu.au

More information: ARM Hub – info@armhub.com.au