Textile waste is a major cause of landfill in Australia with up to 679,000 tons of waste released each year. With accumulating waste, and a keen focus on meeting national priorities, ARM Hub is working with key stakeholders across the textile supply chain to identify innovative solutions to divert large volumes of unsaleable textile donations away from landfill.

Through partnership with The Salvation Army, Kmart and QUT, ARM Hub developed and delivered a series of half day workshops where representatives from each organisation, along with industry experts across the garment supply chain, came together to conceptualise potential solutions. The workshop’s objective was to engage with industry, research organisations and government bodies to develop a plan to assist the sorting of textiles using artificial intelligent systems and robotic equipment. Finding an economically viable way to sort and disaggregate clothing is one of the major barriers to reducing the amount of textile waste in landfill.

Automating parts of the sorting and reprocessing stage, will allow for charitable recyclers to minimise the time and energy needed during the recycling process. With people and robots working collaboratively, a solution can be found that contributes to a circular economy.

Workshopping with the experts

Workshop 1 took place in the ARM Hub Learning Factory in Northgate, Brisbane. Attendees worked together pulling apart a standard 1m3 bale of donated textiles to understand what makes up a typical bale to identify current challenges and opportunities that can be addressed in sorting.

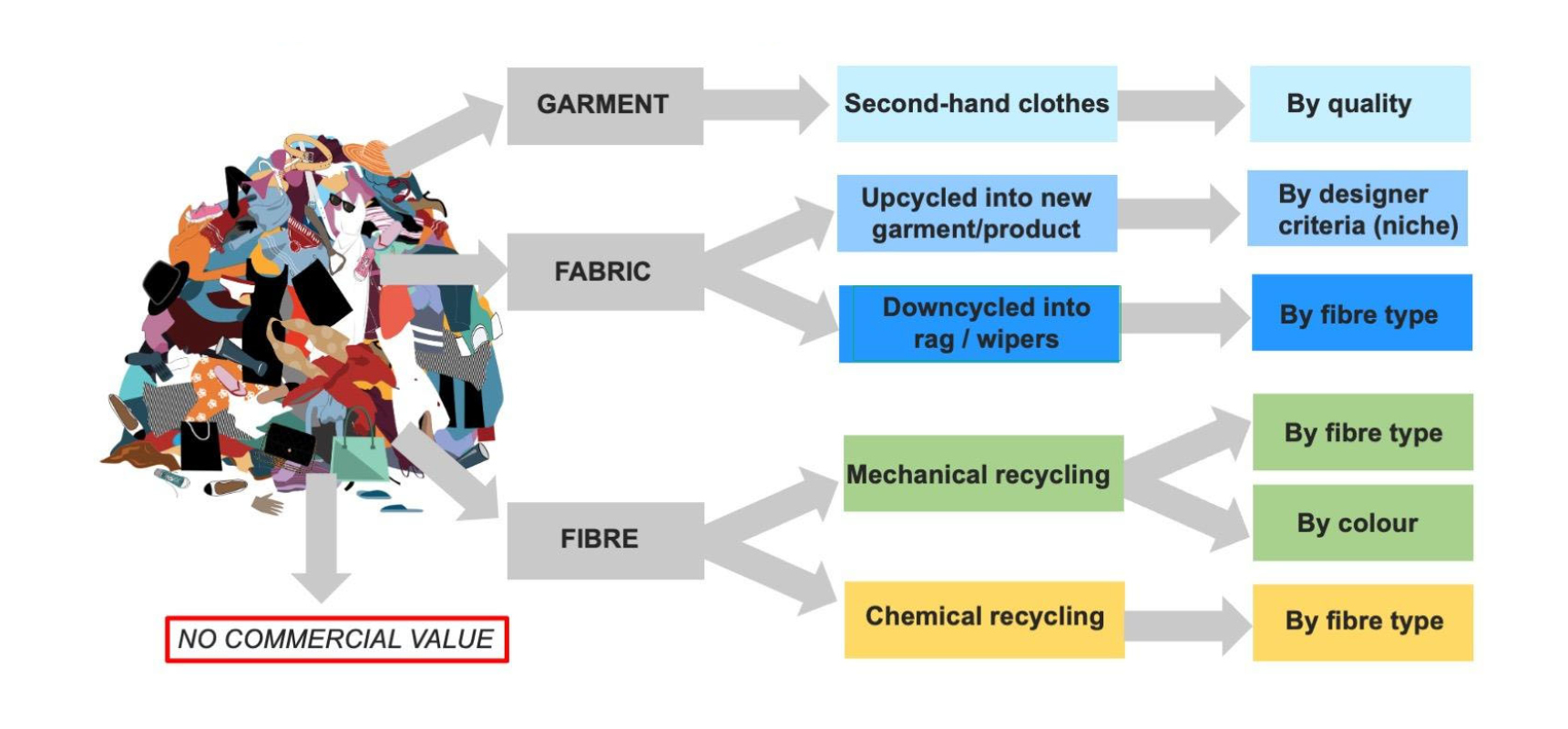

With the array of garments and textiles in each bale, effectively sorting materials into categories for reuse can be time-consuming and labour-intensive.

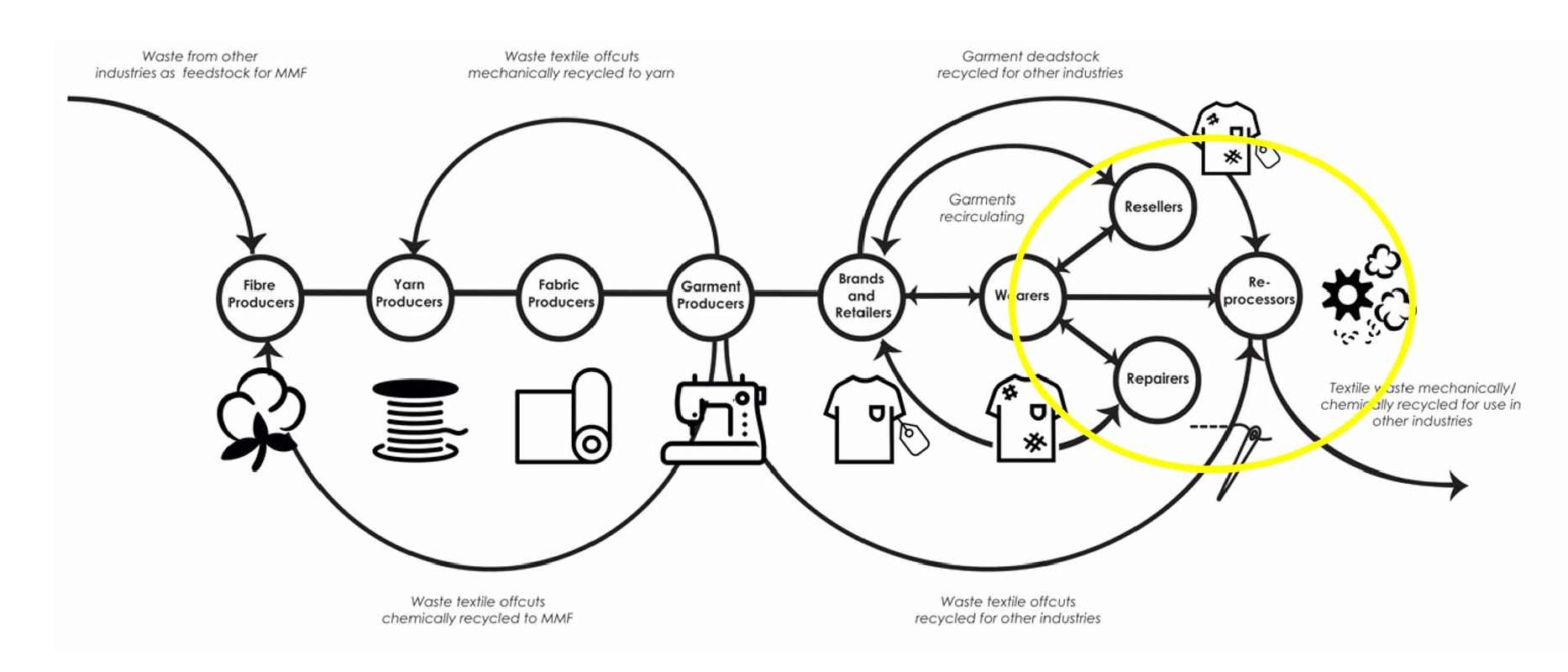

The challenges to the textile industry are well-known. Each garment has a similar lifecycle from the beginning: raw materials come in and are spun, woven or knitted into cloth, stitched into garments, and then sold by retailers to consumers. At each stage in the supply chain, waste is produced, from offcuts to unsellable garments and everything in between. To offset the volume of waste, industry leaders need to take a proactive approach through being drivers of change, such as product stewardship agenda and retailers’ targets around circularity.

Plans for the industry

The completion of the workshops helped identify a stakeholder informed plan to develop a demonstrator for automated sorting and disaggregation. If the project is undertaken, the demonstrator will leverage existing technology and develop novel technology applications to address the identified needs.

ARM Hub is renowned for their work with priority sectors, developing high-tech solutions for a range of industry issues. Through the development of this project, ARM Hub and the partnering parties, will have the opportunity to inform and establish the future standards for fashion manufacturing and textile redistribution, including but not limited to, product design and textile purity.